WSF designs and manufactures Autoclaves, Retorts, and Pressure Vessels to ASME code standards.

WSF also is a single-source supplier of complete systems for a broad range of industrial applications including vulcanizing, high pressure testing, dewaxing, leaching, vacuum-pressure impregnation, ovens, sterilizing and material handling equipment.

Check Out Our Products

Follow one of our links below to your preferred Autoclave application, or choose from our main links above.

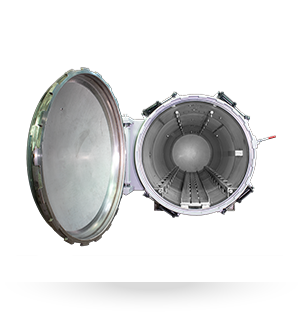

Our RAPIDOOR® link features information on our quick-actuating Autoclave closures.

Composite bonding, laminating, and curing Autoclaves for aircraft, aerospace, automotive, sporting goodsand other industries.

Special Alloy Autoclaves for high temperature and pressure Caustic cleaning and Core leaching processes used by aircraft and investment casting industries.

WSF designs and manufactures custom control systems for Autoclave closures and various Autoclave Process applications.

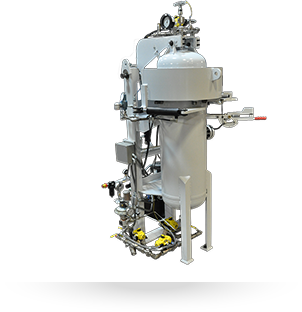

Complete Dewaxing Autoclave systems for the Investment Casting Industry with custom designed pressurize, vent, and draining options.

High Pressure and Hydrostatic Test systems for oceanographic, deep-sea, and pressure testing parts, cable assemblies, and materials evaluation.

WSF designs, manufactures and integrates Material Handling systems with custom Autoclave internal and external product handling requirements.

From Lab Test units to full-scale production model Autoclave Oven systems with variable Temperature, Pressure, and circulation capabilities.

Quick-open Autoclave closures in various horizontal and vertical configurations. Can be supplied for fieldmounting or as a complete Autoclave system.

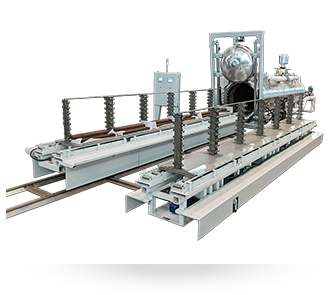

Unique WSF RapidLoader™ design combines our RapiDoor® quick-open closure with an integral product loading and extracting system.

WSF SmartClave® technology is completely scalable and can be fully integrated with our Autoclave Door and Process systems providing support to operators and maintenance personnel.

Stainless and Carbon Steel Autoclaves, Retorts and systems for food, pharmaceutical, medical waste, and cleaning processes, sizes from pilot systems to full production models.

Vacuum Pressure Impregnation systems for electric motor, transformer, electronic component manufacturers. Unique WSF design options save on resin fills and changeover costs.

Vulcanizing Custom horizontal and vertical Autoclave systems with several pressurizing, heat control, venting options available. WSF can provide complete product handling systems fully integrated with the Vulcanizing process control system.

Product Literature

Download application brochures with more details on some of our products.